Learn why mismatched solar panels can reduce efficiency and damage your marine power system, and discover how to select compatible panels for optimal performance.

Understanding Different Types of Hose Clamps and Their Uses in a Boat

The Importance of Using the Right Materials in Marine Plumbing

Unpleasant Toilet Odors Onboard: Expert Solutions by Auckland Marine Systems

Troubleshooting Vacuum Toilet Systems Onboard: Expert Solutions from Our Marine Technicians

Upgrade to a Dripless Seal

ntroduction

For many boat owners, maintaining a dry and clean bilge is a continuous challenge. Traditional stuffing boxes, although functional, can be a significant source of water ingress, requiring regular adjustments and maintenance. Upgrading to a dripless seal can eliminate these issues, providing peace of mind and a cleaner, drier bilge. Auckland Marine Systems is here to assist you with all your boat's propeller shaft needs, ensuring a smooth transition to a dripless seal system.

The Benefits of Upgrading to a Dripless Seal

Replacing your boat's traditional stuffing box with a dripless seal offers several advantages:

Leak Prevention: Dripless seals are designed to create a watertight seal around your boat's propeller shaft, preventing water from entering the bilge. This helps keep your bilge dry and clean, reducing the risk of corrosion and mold growth.

Low Maintenance: Unlike stuffing boxes, dripless seals require minimal maintenance. There is no need for regular adjustments or repacking, which saves you time and effort in the long run.

Increased Durability: Dripless seals are typically made from high-quality materials that are resistant to wear and tear. This means that they generally last longer than traditional stuffing boxes, providing greater value for your investment.

Enhanced Boat Performance: By preventing water ingress, dripless seals can help to improve the overall performance of your boat. A dry bilge can contribute to better weight distribution and fuel efficiency.

How Auckland Marine Systems Can Help

Our team of experienced technicians at Auckland Marine Systems is dedicated to assisting you with upgrading your boat's propeller shaft system. We offer a comprehensive range of services, including:

Expert Consultation: We will assess your boat's current propeller shaft setup and recommend the most suitable dripless seal system based on your vessel's specific requirements.

Seamless Installation: Our skilled technicians will expertly remove your boat's existing stuffing box and install the new dripless seal system, ensuring a perfect fit and optimal performance.

Post-Installation Support: After installation, we provide ongoing support and guidance to help you maintain your new dripless seal system. This includes tips on proper care, maintenance schedules, and potential warning signs to look out for.

Quality Products: At Auckland Marine Systems, we are committed to offering only the highest quality products from reputable manufacturers. This ensures that your upgrade to a dripless seal will be a long-lasting and worthwhile investment.

Conclusion

Upgrading to a dripless seal system can significantly enhance your boat's propeller shaft performance and eliminate the headaches associated with traditional stuffing boxes. Auckland Marine Systems is here to provide expert guidance and services to ensure a seamless transition to a cleaner, drier, and more efficient boat. Contact us today to discuss your needs and let our team of professionals help you make the most of your boating experience.

Enhance Your Boating Experience with Deck Wash Down Pumps: Expert Retrofitting by Our Marine Engineers

Introduction

Keeping your boat's deck clean and well-maintained is essential for both aesthetics and safety. A deck wash down pump is a valuable addition to your vessel, simplifying the cleaning process and ensuring your deck remains in top condition. Our team of skilled marine engineers is here to help you retrofit your boat with a deck wash down pump that perfectly suits your needs, making your boating experience even more enjoyable.

The Benefits of Deck Wash Down Pumps

A deck wash down pump is a powerful tool that streamlines the process of cleaning your boat's deck. These pumps offer several advantages, including:

Efficient Cleaning: Deck wash down pumps use high-pressure water to remove dirt, grime, and salt from your boat's surface. This means you can clean your deck quickly and effectively, without the need for harsh chemicals or excessive scrubbing.

Enhanced Safety: Keeping your boat's deck clean is crucial for preventing slips and falls. A wash down pump allows you to easily maintain a clean and safe environment for you and your passengers.

Prolonged Deck Lifespan: Regular cleaning using a wash down pump helps to protect your boat's deck from damage caused by salt, algae, and other contaminants. This, in turn, can extend the lifespan of your boat's decking and help maintain its value.

Versatility: Deck wash down pumps can be used for various cleaning tasks beyond your boat's deck, such as washing down the hull, anchor, or fishing gear.

Retrofitting a Deck Wash Down Pump with Our Marine Engineers

Our team of marine engineers is ready to assist you in retrofitting a deck wash down pump that is tailored to your specific requirements. Our process includes:

Assessment: Our engineers will assess your boat's layout and design, taking into account factors such as available space, power source, and your desired pressure output.

Pump Selection: Based on our assessment, we will recommend the most suitable deck wash down pump for your vessel. We will help you choose from a range of reliable and high-performance pumps to ensure that your investment will serve you well for years to come.

Expert Installation: Our skilled marine engineers will install your new deck wash down pump with precision, ensuring that it is securely mounted, properly connected to the water supply, and safely wired to your boat's electrical system.

Testing and Demonstration: Once installed, we will test your new wash down pump to ensure it operates effectively and efficiently. Additionally, we will demonstrate how to use the pump and provide maintenance tips to help you get the most out of your investment.

Conclusion

A deck wash down pump is an invaluable addition to any boat, making the task of cleaning and maintaining your vessel's deck simpler and more efficient. Our team of marine engineers is dedicated to helping you retrofit your boat with the perfect wash down pump for your needs. Contact us today to learn more about how we can enhance your boating experience and keep your vessel looking its best.

The Essential Role of Bilge Pumps: Expert Guidance from Our Team of Marine Engineers

ntroduction

As any seasoned boater or marine enthusiast knows, ensuring the safety and efficiency of your vessel is a top priority. One of the most vital components of your boat's safety system is the bilge pump. This often-overlooked piece of equipment can be a lifesaver in preventing damage and keeping your vessel afloat. Our team of experienced marine engineers is here to help you choose the right bilge pump and professionally install it, ensuring that your boating adventures are smooth sailing.

The Importance of Bilge Pumps

A bilge pump is a critical component of your boat's safety system, serving to remove excess water from the bilge area (the lowest part of a vessel's hull). Water can enter your boat through various means, such as rain, waves, or even leaks. If left unchecked, this water can lead to several issues, such as mold, corrosion, and even the sinking of your boat.

A reliable bilge pump system is crucial to:

Maintain Buoyancy: A bilge pump ensures that excess water is removed from your boat, keeping it buoyant and preventing it from sinking.

Protect Essential Systems: Water in the bilge area can damage critical components of your boat, such as the engine, electrical system, and steering mechanisms. A bilge pump helps prevent these costly repairs.

Reduce Moisture and Mold: By removing excess water, bilge pumps help to reduce moisture levels within your boat, preventing mold growth and maintaining a healthy environment for passengers.

Choosing the Right Bilge Pump

Selecting the appropriate bilge pump for your vessel depends on a few key factors:

Boat Size: Larger boats require more powerful bilge pumps to effectively remove excess water. Our marine engineers can help you determine the right pump capacity for your boat based on its size and design.

Automatic vs. Manual: Automatic bilge pumps turn on when water is detected, while manual pumps require the user to activate them. Automatic pumps are more convenient and can be crucial in emergency situations when rapid water removal is necessary.

Pump Type: There are various types of bilge pumps, such as centrifugal, diaphragm, and flexible impeller pumps. Each has its own advantages and drawbacks, so it's essential to consult with a marine engineer to determine the best option for your vessel.

Professional Installation

Having your bilge pump professionally installed by our team of marine engineers ensures optimal performance and safety. Our experts will:

Assess your vessel's needs and recommend the most suitable bilge pump.

Properly position the pump in the bilge area to maximize efficiency and water removal.

Ensure that the pump's wiring is correctly and safely installed, minimizing the risk of electrical issues.

Test the pump to confirm its functionality and effectiveness.

Conclusion

The importance of a bilge pump cannot be overstated. It is a crucial piece of equipment that can save your boat from potential disaster. Our team of marine engineers is dedicated to helping you choose the right bilge pump for your vessel and ensuring its professional installation. Reach out to us today, and let us help keep your boating adventures safe and worry-free.

Navigating Marine Toilets: Choosing and Installing the Perfect One for Your Boat

Sail in Comfort: Let Our Marine Engineering Experts Help You Choose and Install the Perfect Toilet for Your Boat

Introduction

Are you looking to upgrade or install a marine toilet on your boat? At Auckland Marine Systems, our team of skilled marine engineering professionals is here to assist you in selecting and installing the perfect toilet to ensure a comfortable and convenient experience on the water. With years of experience and a dedication to customer satisfaction, we guarantee that your boat's facilities will be the perfect match for your needs.

Why Choose Auckland Marine Systems?

Expertise: Our team of certified marine engineers is well-versed in the different types of marine toilets, their features, and installation requirements. We can help you make an informed decision based on your boat's size, design, power, and water supply.

Customized solutions: We understand that every boat is unique, and our experts will work closely with you to tailor a solution that fits your specific needs and preferences.

Quality workmanship: We take pride in providing top-notch installation services, ensuring that your new marine toilet is properly installed, secure, and leak-free.

Comprehensive support: From initial consultation to post-installation maintenance, our team is committed to providing exceptional customer support every step of the way.

Our Marine Toilet Services

Consultation: We will assess your boat's head compartment, electrical and water systems, and holding tank capacity to recommend the best marine toilet options for your needs, from manual pump toilets to high-tech vacuum flush models.

Professional installation: Our skilled engineers will expertly install your chosen marine toilet, ensuring a secure fit and proper connection to your boat's plumbing and electrical systems.

Maintenance and repair: Keep your marine toilet running smoothly with our professional maintenance and repair services. We can diagnose and resolve any issues, ensuring your toilet remains efficient and reliable.

Upgrades and accessories: Enhance your boat's bathroom facilities with our range of upgrades and accessories, including electric pumps, vacuum generators, vent filters, and more.

Let Auckland Marine Systems Take Care of Your Marine Toilet Needs

Don't let an outdated or poorly functioning marine toilet put a damper on your boating experience. Trust the experts at Auckland Marine Systems to help you choose and install the perfect marine toilet for your boat. Contact us today to schedule a consultation and experience the difference our professional services can make. Sail in comfort and enjoy the peace of mind knowing that your boat's facilities are in the best hands.

Three Hot Water Installation Options for Your Vessel

Explore three hot water installation options for your boat - wet back off the engine, diesel water heaters, and 230V from shore power - and discover the benefits of each. In this blog post, we'll discuss these solutions and how our expert team can install the perfect system to meet your needs, ensuring you enjoy the convenience and comfort of hot water onboard your vessel.

Replacing Rusted Metal Tanks with Durable, Inert Plastic Welded Tanks

Introduction:

Replacing old, rusted metal tanks on your vessel with modern, inert plastic welded tanks can improve safety, efficiency, and reliability. These tanks are suitable for various applications, including fuel storage, holding tanks, and freshwater storage. In this blog post, we'll discuss the benefits of making the switch and outline how our expert team can help you remove and replace your old metal tanks with high-quality plastic alternatives.

Benefits of replacing rusted metal tanks with plastic welded tanks:

There are several advantages to upgrading your vessel's tanks to plastic welded options:

a. Corrosion resistance: Unlike metal tanks, plastic tanks are resistant to rust and corrosion, ensuring a longer lifespan and reduced maintenance costs. b. Lightweight: Plastic tanks are typically lighter than their metal counterparts, which can help improve your vessel's fuel efficiency and handling. c. Customizable: Plastic tanks can be custom-fabricated to fit the unique dimensions and contours of your vessel, maximizing available space. d. Chemical resistance: Inert plastic tanks are resistant to a wide range of chemicals, making them suitable for various applications, including fuel and wastewater storage.

Removing old, rusted metal tanks:

Our team of skilled technicians will carefully remove your vessel's existing metal tanks, ensuring minimal disruption to your boat's structure and systems. The removal process includes:

a. Draining and cleaning: We'll safely drain any remaining fuel, water, or waste from the tank and clean it thoroughly to minimize environmental impact and potential hazards. b. Detaching connections: Our technicians will disconnect all hoses, pipes, and wiring associated with the tank, carefully labeling them for reattachment to the new plastic tank. c. Extraction: We'll safely remove the rusted metal tank from your vessel, using specialized equipment and techniques to prevent damage to the surrounding structure.

Installing new plastic welded tanks:

Once the old metal tank has been removed, our team will expertly install your new plastic welded tank. The installation process includes:

a. Custom fabrication: If necessary, we'll custom-fabricate the plastic tank to fit the specific dimensions and contours of your vessel, ensuring an optimal fit and efficient use of space. b. Tank preparation: We'll ensure that the new plastic tank is clean and ready for installation, inspecting it for any potential issues or defects. c. Reconnecting systems: Our technicians will carefully reconnect all hoses, pipes, and wiring to the new plastic tank, ensuring a seamless integration with your vessel's existing systems. d. Leak testing: After installation, we'll perform a thorough leak test to verify that all connections are secure and the tank is functioning correctly.

Conclusion:

Replacing your vessel's old, rusted metal tanks with durable, inert plastic welded tanks is a smart investment in safety, efficiency, and reliability. Our expert team can handle every step of the process, from removal and custom fabrication to installation and post-installation support. Make the switch to plastic welded tanks today, and experience the benefits of a more reliable, long-lasting storage solution for your fuel, holding tanks, or freshwater needs.

LectroScan Treatment Plant Servicing: Keeping Your System in Optimal Condition

A LectroScan treatment plant plays a vital role in managing a vessel's wastewater, ensuring compliance with environmental regulations. Regular maintenance and servicing are essential to keep the system functioning efficiently and avoid potential issues. In this blog post, we'll discuss how our skilled technicians can service your vessel's LectroScan treatment plant, ensuring it stays in optimal working condition.

Expert Desalination Plant Installation on Your Pleasure Craft: Choose the Best System for Your Needs

Sailing enthusiasts and pleasure craft owners know the value of having a reliable source of fresh water while cruising the open seas. Our marine engineering company specializes in installing desalination plants that efficiently convert seawater into freshwater, ensuring a consistent supply on your vessel. In this blog post, we'll guide you through selecting the ideal desalination system for your needs and discuss how our expert team can help you with a seamless installation.

Marine Engine Alignment

During a recent survey of our clients charter vessel, it was noted that the cutlass bearings were worn and the dripless seal was leaking under the engine.

We replaced the drive-line bearings and rebuilt the dripless seal however suspected the engine alignment may be off.

When a boat is on the hard, it flexes and bends in a way that it would not while sitting in the water, making drive-line alignment impossible to do accurately. We checked the alignment on the hard and it looked close, however informed the client we needed to do a final check/adjustment on the water.

When the boat launched, the new dripless seal began leaking immediately, indicating that the alignment was badly out. The shaft was pressing down on one side of the seal allowing a gap at the top.

After measuring the alignment accurately back on the water, it was found to be 16 thousandths of an inch out. In order to get this running true, the engine needed to be lifted approximately 5mm at the aft end.

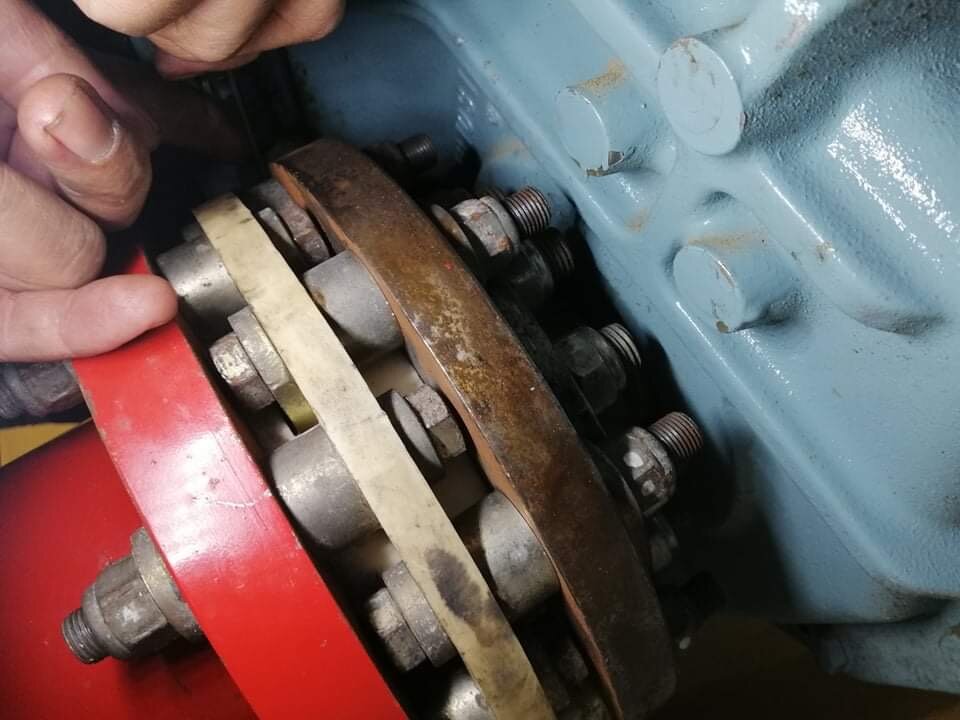

Being that the engine was hard mounted, we had some custom shims lazer cut. We slipped them under the engine mounts until we measured that the drive-line was running true.

No more leaky shaft and no more worn bearings.

Jabsco toilet leaking from manual pump shaft

Nobody wants water leaking from their toilet, so when a customer got in contact with us to repair their leaking toilet we were pleased to find it wasn’t the toilet that was leaking but the shaft of the hand pump. The water was then tracking down and giving the impression of a bowl leak.

This was a simple fix with an inexpensive part. Now the head is dry again.

Cummins Onan Genertator Fault

A new client had mentioned that no mater how many times he changed his impeller on His Cummins Onan Marine Generator, the same fault code kept coming up. “Loss of Raw Water Flow”

It didn’t take us long to suggest that perhaps his heat exchanger might be blocked up, causing a flow restriction through the generator.

Our owner agreed to let us inspect it and yes, sure enough half the tubes inside the heat exchanger were blocked with calcium build up and the others were blocked by old pieces of nitrile impeller that the previous service agent had not checked for.

We removed the cooler from the boat and brought it back to the workshop for a service.

This fixed the problem and now our new client has a working generator again.

If your impeller comes out with missing fins, remember….they will still be inside the heat exchanger somewhere.

Extracting a Volvo TAMD31A

Stay Cozy Onboard: Diesel Air Heater Installation for Your Vessel by Our Marine Engineering Experts

Introduction:

As a boat owner, you know that staying warm and comfortable onboard during colder months can be a challenge. Our marine engineering business is here to help you enhance your boating experience by offering professional diesel air heater installation services. In this blog post, we'll discuss the benefits of diesel air heaters and how our expert team can seamlessly install one on your vessel, ensuring a cozy and enjoyable time on the water.

Advantages of diesel air heaters for your vessel:

Diesel air heaters offer several benefits that make them a top choice for boat owners looking to stay warm onboard:

a. Energy efficiency: Diesel air heaters are known for their fuel efficiency, consuming minimal fuel while providing consistent and powerful heat output. b. Quiet operation: Modern diesel air heaters are designed to run quietly, allowing you to maintain a peaceful atmosphere onboard your vessel. c. Low maintenance: Diesel air heaters typically require less maintenance than other heating options, making them a hassle-free choice for boat owners. d. Compact size: Diesel air heaters are compact and can be installed in various spaces on your vessel, ensuring minimal disruption to your boat's layout.

Expert installation by our marine engineering team:

Our skilled marine engineers have the knowledge and experience necessary to install your diesel air heater professionally and efficiently. Our installation process includes:

a. Assessment and planning: We'll evaluate your vessel's layout and heating requirements to determine the optimal location and size of the diesel air heater. b. Installation: Our team will expertly install the diesel air heater, ensuring proper connections to your boat's fuel supply, electrical system, and ventilation. c. Testing and calibration: After installation, we'll test the heater's performance and make any necessary adjustments to ensure optimal heat output and efficiency. d. Safety precautions: Our technicians prioritize safety, adhering to industry standards and best practices for diesel air heater installation to minimize any risks.

Ongoing support and maintenance:

We're committed to providing comprehensive support even after the installation is complete. Our ongoing support and maintenance services include:

a. Routine inspections: At your request, our marine engineers can periodically inspect your diesel air heater to ensure it's operating efficiently and safely. b. Maintenance guidance: We'll provide recommendations for proper care and maintenance of your diesel air heater, helping you extend its lifespan and maintain peak performance. c. Troubleshooting and repairs: In the unlikely event of an issue with your diesel air heater, our team will be ready to troubleshoot and perform any necessary repairs.

Conclusion:

Stay cozy and comfortable onboard your vessel with a professionally installed diesel air heater. Our marine engineering team is dedicated to providing top-notch installation, support, and maintenance services, ensuring that you can enjoy a warm and inviting boating experience. Contact us today to learn more about our diesel air heater installation and how we can help you enhance the comfort of your vessel.

A Chinese copy of the webasto installed into a clients boat. Costing a fraction of the price of an original.