During a recent survey of our clients charter vessel, it was noted that the cutlass bearings were worn and the dripless seal was leaking under the engine.

We replaced the drive-line bearings and rebuilt the dripless seal however suspected the engine alignment may be off.

When a boat is on the hard, it flexes and bends in a way that it would not while sitting in the water, making drive-line alignment impossible to do accurately. We checked the alignment on the hard and it looked close, however informed the client we needed to do a final check/adjustment on the water.

When the boat launched, the new dripless seal began leaking immediately, indicating that the alignment was badly out. The shaft was pressing down on one side of the seal allowing a gap at the top.

After measuring the alignment accurately back on the water, it was found to be 16 thousandths of an inch out. In order to get this running true, the engine needed to be lifted approximately 5mm at the aft end.

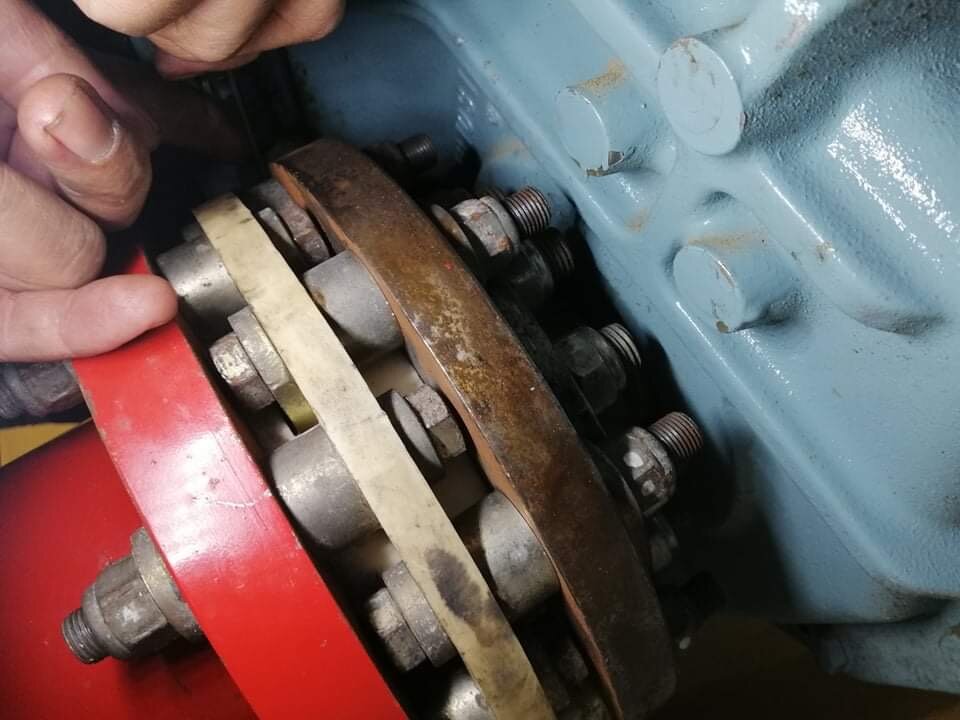

Being that the engine was hard mounted, we had some custom shims lazer cut. We slipped them under the engine mounts until we measured that the drive-line was running true.

No more leaky shaft and no more worn bearings.